Cut or use different tubing if any imperfections are found. The purpose of adding double flared brake lines to a vehicle is to minimize friction wear along with cracking at the flare that has the potential to create a leak within the line.

This set of tools is believed to work best on annealed steel and dead soft.

Brake line double flare. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. A single flare is just as it sounds the line is flared out just once in a conical shape. Single flares are not acceptable for brake lines and tend to crack and leak quite easily.

A double flare is one of the most common flares found on vehicles. YOTOO Double Flaring Tool Kit Brake Line Flaring Tools for Copper Aluminum Soft Steel Brake Line and Brass Tubing Tool Kit. 39 out of 5 stars 161.

5 coupon applied at checkout Save 5 with coupon. Get it as soon as Mon Feb 8. FREE Shipping on orders over 25 shipped by Amazon.

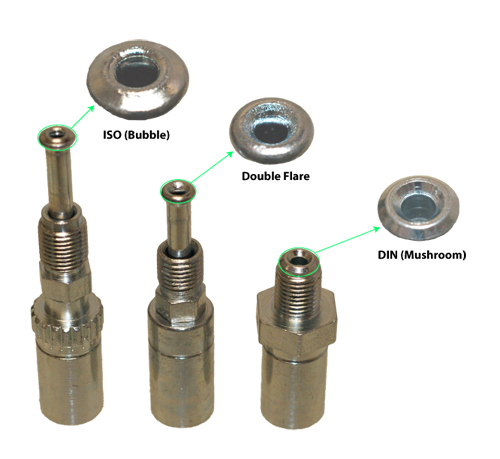

The double flare brake line fitting is quite common in automobiles made sold and driven throughout the United States and Asia. The purpose of adding double flared brake lines to a vehicle is to minimize friction wear along with cracking at the flare that has the potential to create a leak within the line. There are two basic types of flares used on OEM automotive brake systems throughout the world.

The SAEdouble inverted45degree flare and the DINISO bubble flare. We will refer to them as SAE or DIN flare. The most common is the SAE flare.

Typically found on all American and Asian cars but the European style DIN flare is appearing everywhere now. Brake Lines- To Double Flare or not to Double Flare. I did just change a master cylinder had 3 lines instead of two and oh I got angry at the bottom one that was stuck.

For a tiny car and needed to reflareafter breaking the old one off inside the cylinder. We have the best Tube Flaring Tool for the right price. Buy online for free next day delivery or same day pickup at a store near you.

Brake Line Flaring Tool - Hydraulic Flaring Tool Kits. More information about our privacy practicesmore information about our privacy practices. Brake Line Flaring Like a Pro.

The Eastwood Pro Brake Flaring Tool lets you create three kinds of precision flares in any of five sizes of tubing in minimal time. A good flare is an essential part of your brake transmission cooler or fuel lines as it ensures they will connect solidly without any leaks. Double Flaring Brake Lines 1 Adjust the height of the tube so it reaches the height of your flaring anvil.

The anvil is round piece with a small rod sticking out the top. This is a leveraged manual flaring tool. It uses quick-set dies and a lever-actuated ram to press the flaring heads into the line.

You can make a double flare in a matter of seconds with these kits. How to Make a Double Flare. We will focus on how to use the manual flaring tool.

The first step is to cut the line. The double flare is similar to the most basic flare called single flare but more durable. Brake Line Flaring Tool Ultimate Guide Manufacturers from all over the world adapted double flares for all the brake lines but still you would find bubble flares in the vehicles manufactured in the European countries.

Double flares are necessary for brake lines due to the high pressures inflicted on them by the hydraulic system. Single flared lines are only appropriate for low-pressure lines due to their tendency to crack or leak. The brake system cannot afford to have a leak in the lines since this can cause serious injury or death if the brakes fail.

The master brake flaring tool will make the process of repairing your brake line quite comfortable. The OTC 6502 kit covers different types of flares including bubble double and single flares. It comes along with other tools you will need for a perfect finish such as adapters tube cutter an arbor press flaring bar and deburring tool.

Brake lines will leak at the flare when there is a poor connection with the seat of the fitting. This type of leak is commonly known as a weep. It is the result of a tiny imperfection in the flare that occurs while flaring the tube.

BokWin SAE 45 Degree Automotive Double Flare Brake Line Flaring Tool Kit with 316 14 516 38 12 Adapters for Copper Aluminum Soft Steel Brake Line and Brass Tubing Tool Kit. Step 1 Place the cone over the end of the tubing and move it down until the cone is centered. On a generating flare tool the flare is formed in the air instead of in the recessed part of the barStep 2 Turn the advance screw several revolutions.

Check the manual for the number of revolutions needed for the flare size you needStep 3 Check the new flare for any imperfections such as splits. Cut or use different tubing if any imperfections are found. GM fuel and brake lines 516 38 45 degree and double flare 316 ¼ 516 3812 ISO Bubble flare 475 6 8 10 mm.

This set of tools is believed to work best on annealed steel and dead soft. It has a substantial and sturdy construction that makes it a durable set.